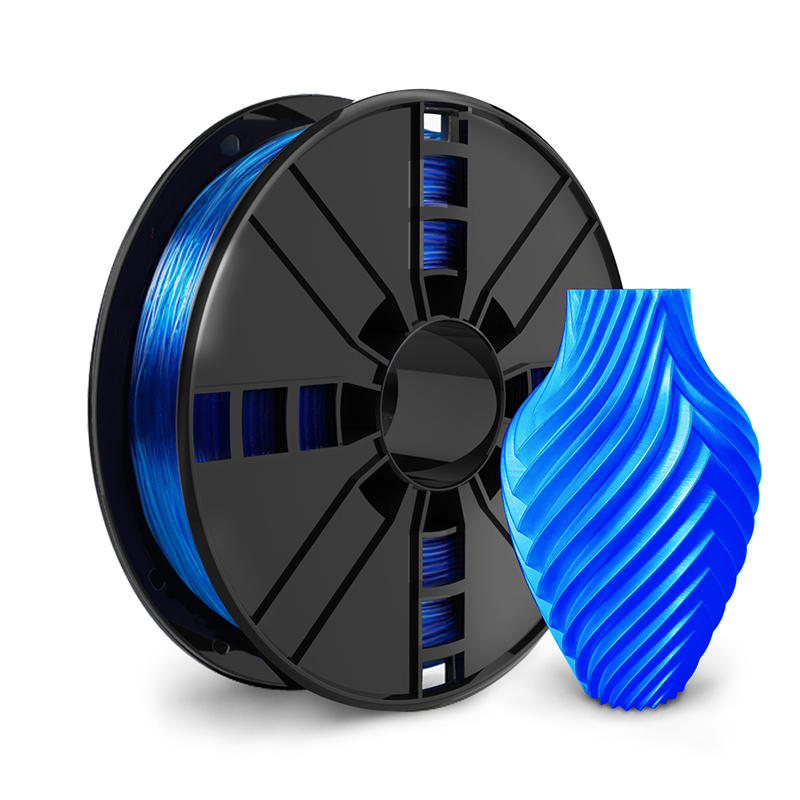

Filament ya 3D yoroshye TPU y'ubururu 1.75mm Shore A 95

Ibiranga Ibicuruzwa

| Ikirango | Torwell |

| Ibikoresho | Polyurethane ya Thermoplastic yo mu rwego rwo hejuru |

| Ingano | 1.75mm/2.85mm/3.0mm |

| Uburemere rusange | 1 Kg/igikombe; 250g/igikombe; 500g/igikombe; 3kg/igikombe; 5kg/igikombe; 10kg/igikombe |

| Uburemere rusange | 1.2Kg/igice kimwe |

| Ukwihanganirana | ± 0.05mm |

| Uburebure | 1.75mm (1kg) = 330m |

| Ibidukikije byo kubika | Yumye kandi ifite umwuka uhumeka |

| Aho kumisha | 65˚C mu gihe cy'amasaha 8 |

| Ibikoresho by'inkunga | Shyiraho Torwell HIPS, Torwell PVA |

| Kwemeza icyemezo | CE, MSDS, Reach, FDA, TUV na SGS |

| Ijyanye na | Makerbot, UP, Felix, Reprap, Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, MK3, AnkerMaker n'izindi mashini zose za FDM 3D printers. |

| Pake | 1kg/igikombe; Ibikombe 8/gitn cyangwa ibikombe 10/gitn ishashi ya pulasitiki ifunze neza irimo imiti yo gusukura |

TorwellUmugozi wa TPU urangwa n'imbaraga zawo nyinshi n'uburyo bworoshye bwo gukora, nk'uruvange rwa plastiki na rubber.

95A TPU ifite ubushobozi bwo kudashwanyagurika cyane kandi ikagira ubushobozi bwo gukandagira buhoro ugereranije n'ibice bya rubber, cyane cyane iyo ishyizwemo ibintu byinshi.

Ugereranyije n'udupira dusanzwe nka PLA na ABS, TPU igomba gukoreshwa buhoro cyane.

Amabara menshi

Ibara riraboneka

| Ibara ry'ibanze | Umweru, Umukara, Umutuku, Ubururu, Umuhondo, Icyatsi kibisi, Imvi, Umuhondo, Ibonerana |

| Emera ibara rya PMS ry'umukiriya | |

Imurikagurisha ry'icyitegererezo

Pake

Umuzingo wa kilo 1TPU ya 3Dhamwe n'umuti wo kuvura indwaraimashini ikoresha umwuka udafite umwuka ipaki

Buri gasanduku kari mu gasanduku kari ukwako (agasanduku ka Torwell, agasanduku ka Neutral, cyangwa agasanduku kabigeneweirahari)

Udusanduku 8 kuri buri gakarito (ingano y'agakarito ni 44x44x19cm)

Bisabwa ku bakoresha imashini zicapa zifite icyuma gisohora amajwi (direct drive extruder), gifite ubugari bwa 0.4 ~ 0.8mm.

Ukoresheje Bowden extruder ushobora kwita cyane kuri izi nama:

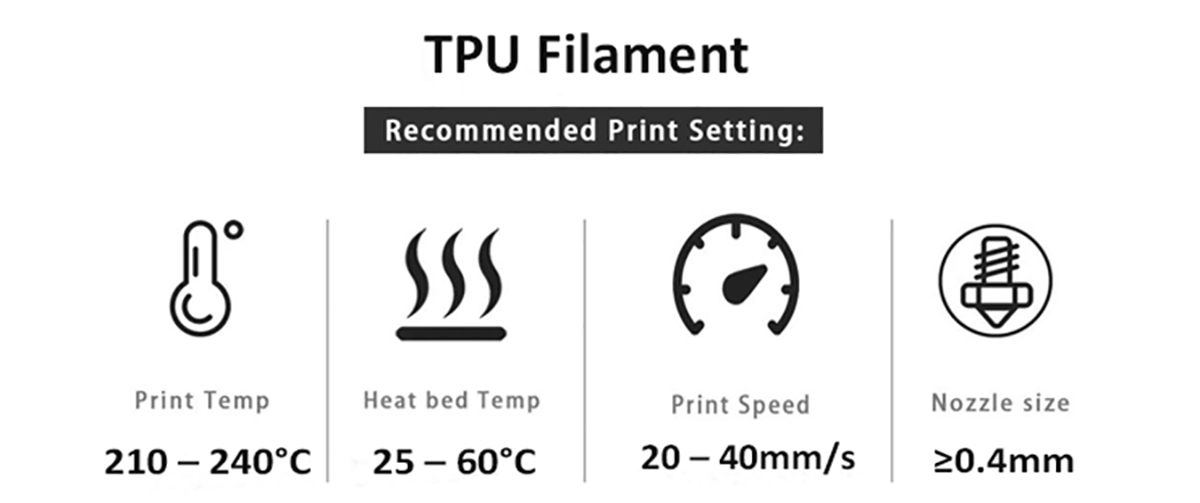

- Capa buhoro 20-40 mm/s Umuvuduko wo gucapa

- Igenamiterere rya mbere ry'urwego. (Uburebure 100% Ubugari 150% umuvuduko 50% urugero)

- Gusubiza inyuma byarahagaritswe. Ibi byagabanya umusaruro wo gucapa mu buryo buteye akajagari, butera imigozi cyangwa bugatera amazi.

- Kongera icyiyongera (Ntabwo ari ngombwa). Shyira kuri 1.1 byafasha guhuza neza filament. - Gukonjesha umuyaga nyuma y'icyiciro cya mbere.

Niba ufite ikibazo cyo gucapa ukoresheje imigozi yoroshye, icya mbere, kandi ikiruta byose, gabanya umuvuduko wo gucapa, gukoresha 20mm/s bizagufasha neza.

Ni ngombwa ko iyo ushyizemo filament uyireka igatangira gusohora. Iyo ubonye filament isohoka, hita uhagarika. Uburyo bwo kuyishyiramo butuma filament inyura vuba kurusha uko isanzwe igaragara, ibi bishobora gutuma ifatwa n'ibikoresho byo kuyisohora.

Nanone shyira filament ku cyuma gisohora amazi mu buryo butaziguye, ntubinyujije mu muyoboro w'ibikoresho. Ibi bigabanya gukurura filament bishobora gutuma icyuma gitemba ku cyuma gisohora amazi mu buryo butaziguye.

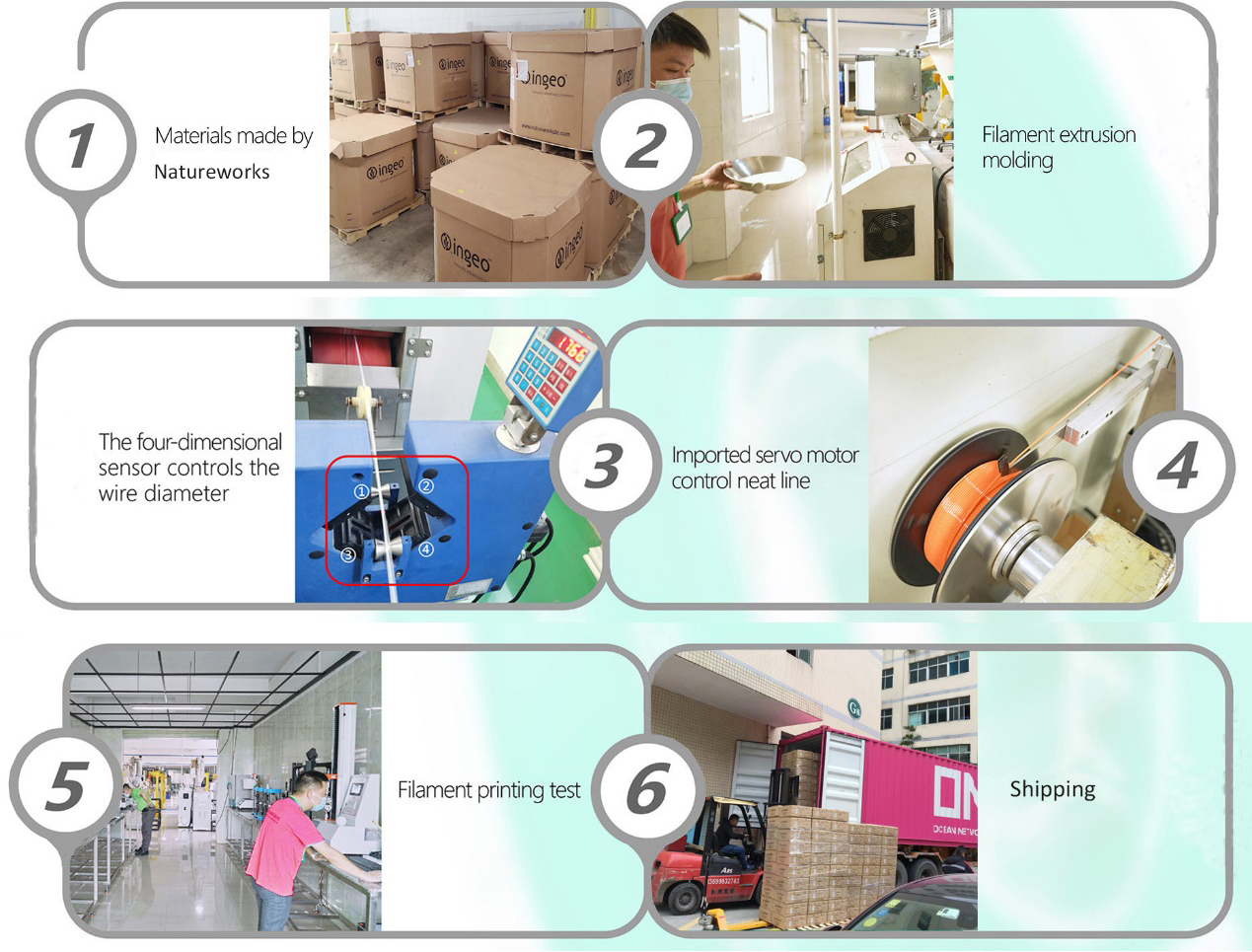

Ikigo cy'uruganda

Ibibazo Bikunze Kubazwa

A: Yego, ibikoresho byose bya TPU bishobora gusigwa irangi. Nkoresha "Tulip Colorshot Fabric Spray Paint". Bifata neza igice cya TPU kandi ntibisiga ku ntoki zawe cyangwa ku myenda yawe. Bikuma mu gihe cy'isaha imwe cyangwa munsi yayo. Nanone nkoresha imbunda ishyushya kugira ngo yumuke mu minota mike. Ushobora no gukoresha icyuma cyuma. Ushobora guhitamo umugozi wa TPU w'ibara ry'umukara nk'ibara ridafite aho ribogamiye, hanyuma ugasiga irangi riri hejuru mu mabara atandukanye batanga. Ibyo nibyo nkora kandi bikora neza.

A: TPU yakuye kuri TorwellIfite impumuro nke cyane ugereranyije na PLA. Nta mpumuro ifite nkuko nabibonye na gato kandi nfungura imashini ikoresha Flex. Ku bijyanye n'uburozi sinzi, ariko impumuro yayo ntabwo ari ikibazo.

A: TPU ikora neza kurusha PLA igihe cyose bibaye ngombwa. TPU itanga uburambe bwinshi kandi irwanya ingaruka zikomeye. PLA irakundwa kurusha TPU mu gihe uburyo bworoshye bwo gucapa ari bwo bwiza, kugira ngo ibintu bigire imbaraga kandi bifite ubuziranenge bwiza. TPU ishobora gukoreshwa mu bice by'imikorere nk'uburyo bwo kuyikoresha.

A: Yego, TPU ni agace karinda ubushyuhe gafite ubushyuhe bw'ikirahure bwa dogere selisiyusi 60. Ubushyuhe bwo gushonga bwa TPU buri hejuru ya PLA.

A: Umuvuduko wo gucapa kuri filament ya TPU uhinduka hagati ya milimetero 15-30 ku isegonda ariko nta ngaruka ku bwiza.

| Ubucucike | 1.21 g/cm3 |

| Igipimo cy'umuvuduko w'amazi ashongeshejwe (g/iminota 10) | 1.5(190℃/2.16kg) |

| Ubukomere bw'Inkombe | 95A |

| Imbaraga zo Gufata | 32 MPa |

| Kurekura mu gihe cyo kuruhuka | 800% |

| Imbaraga zo Kongera Uburemere | / |

| Modulus yo kugongana | / |

| Imbaraga z'ingaruka za IZOD | / |

| Kuramba | 9/10 |

| Uburyo bwo gucapa | 10/6 |

| Ubushyuhe bwo gusohora (℃) | 210 – 240℃ Ubushyuhe busabwa 235℃ |

| Ubushyuhe bwo ku buriri (℃) | Ubushyuhe buri hagati ya 25 na 60°C |

| Ingano y'akazuru | ≥0.4mm |

| Umuvuduko w'umufana | Ku 100% |

| Umuvuduko wo gucapa | 20 – 40mm/s |

| Igitanda gishyushye | Ubusa |

| Ahantu hasabwa kubaka | Ikirahure kirimo kole, impapuro zo gupfuka, kaseti y'ubururu, BuilTak, PEI |