Imashini ya Silk Shiny Fast Color Gradient Change Rainbow Multicolored 3D Printer PLA Filament

Ibiranga Ibicuruzwa

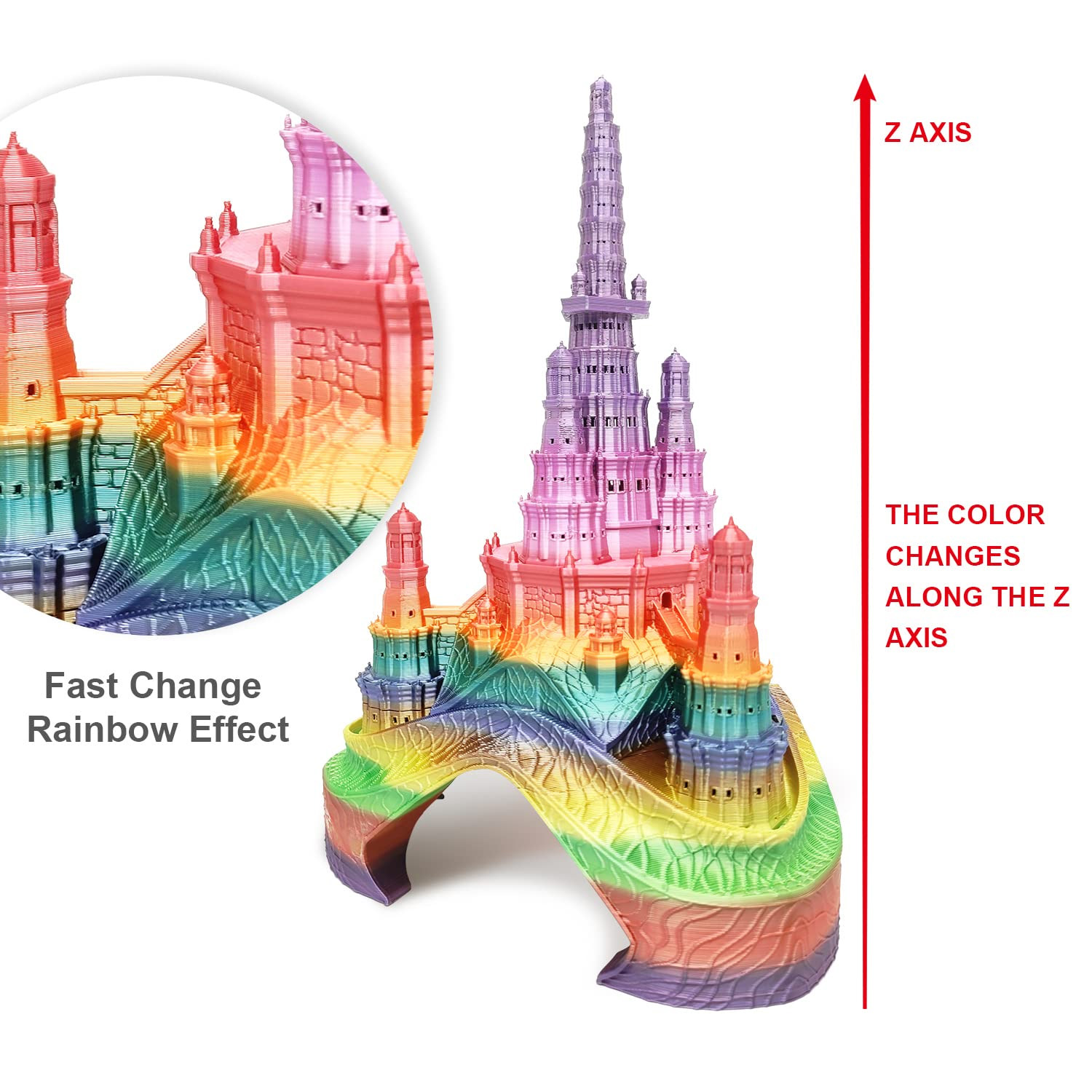

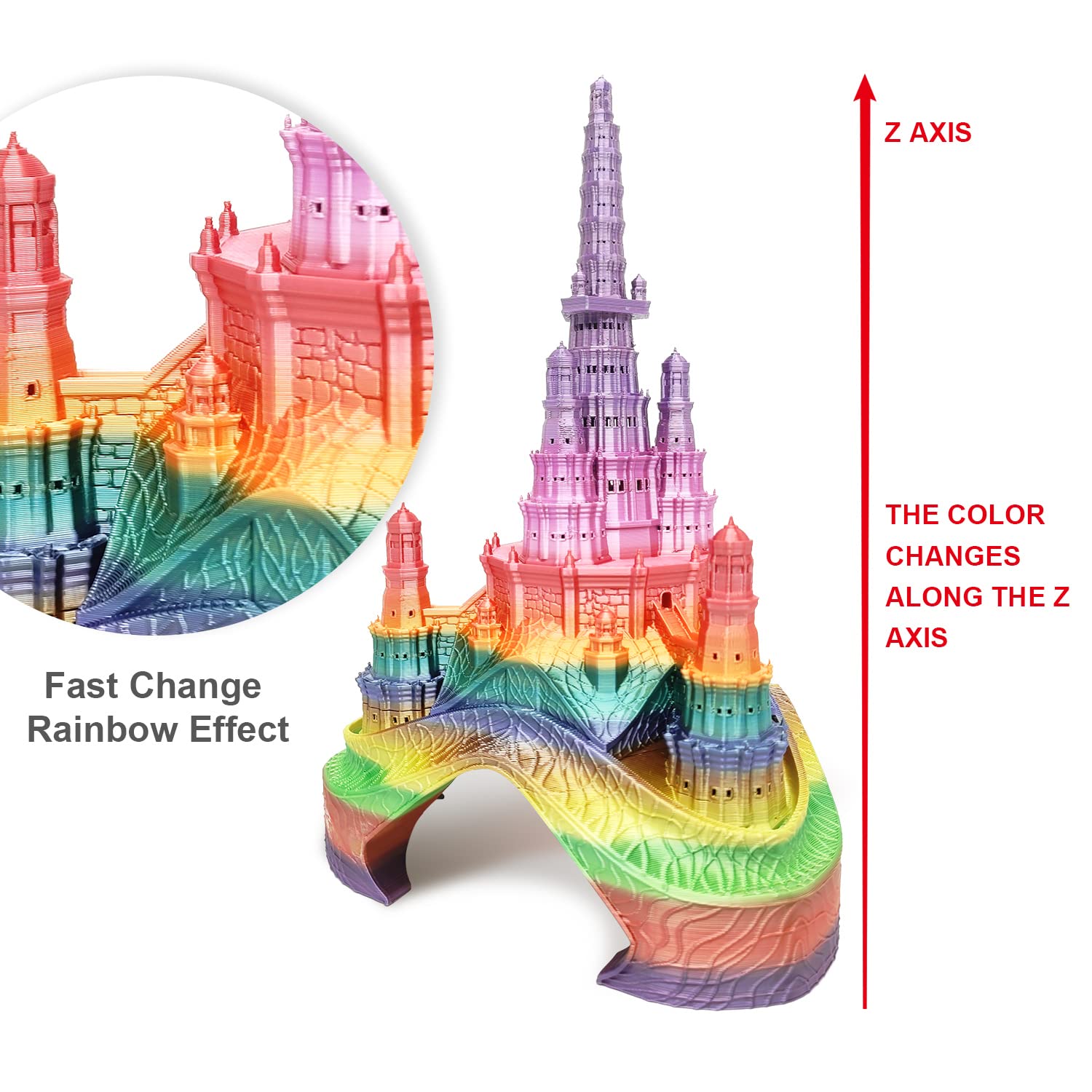

Ikintu cyihariye cya Torwell Rainbow Multicolor Silk PLA filament ni uko ifite ibara ry’umukororombya. Ibikoresho bigizwe n’uruvange rwa PLA n’ibindi bintu, bigatuma habaho amabara menshi ku kintu cyacapwe, bigatuma kiba cyiza cyane mu gukora ibintu by’ubugeni n’imitako. Byongeye kandi, Torwell Rainbow Multicolor Silk PLA filament ifite imiterere myiza ya mekanike n’ubuso burabagirana, bigatuma ikintu cyacapwe gikoreshwa neza kandi kirambye.

| Ikirango | Torwell |

| Ibikoresho | ibinyabutabire bya polymer Pearlescent PLA (NatureWorks 4032D)) |

| Ingano | 1.75mm/2.85mm/3.0mm |

| Uburemere rusange | 1 Kg/igikombe; 250g/igikombe; 500g/igikombe; 3kg/igikombe; 5kg/igikombe; 10kg/igikombe |

| Uburemere rusange | 1.2Kg/igice kimwe |

| Ukwihanganirana | ± 0.03mm |

| Uburebure | 1.75mm (1kg) = 325m |

| Ibidukikije byo kubika | Yumye kandi ifite umwuka uhumeka |

| Aho kumisha | 55˚C mu masaha 6 |

| Ibikoresho by'inkunga | Shyiraho Torwell HIPS, Torwell PVA |

| Kwemeza icyemezo | CE, MSDS, Reach, FDA, TUV na SGS |

| Ijyanye na | Gusubiramo, Ultimaker, End3, Kurema3D, Kuzamura3D, Prusa i3, Z.ortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker n'izindi printer za FDM 3D |

Imurikagurisha ry'icyitegererezo

Amabara menshi y'umukororombya udasanzwe wa Silika:

Ni ibara ry'ubugari, buri metero 3 - 5 zihindura ibara, ni ibintu bitunguranye guhindura ibara rimwe ujya irindi; ni byiza gucapa ibintu byinshi bidasanzwe mu gitambaro kimwe gishyigikira udushya n'igishushanyo cyawe mu Isi y'Icapiro rya 3D neza cyane!

Impamyabushobozi:

ROHS; REACH; SGS; MSDS; TUV

| Ubucucike | 1.21 g/cm3 |

| Igipimo cy'umuvuduko w'amazi ashongeshejwe (g/iminota 10) | 4.7(cyangwa190℃/2.16kg) |

| Ubushyuhe bwo kugoreka ubushyuhe | 52℃, 0.45MPa |

| Imbaraga zo Gufata | 72 MPa |

| Kurekura mu gihe cyo kuruhuka | 14.5% |

| Imbaraga zo Kongera Uburemere | 65 MPa |

| Modulus yo kugongana | 1520 MPa |

| Imbaraga z'ingaruka za IZOD | 5.8kJ/㎡ |

| Kuramba | 4/10 |

| Uburyo bwo gucapa | 9/10 |

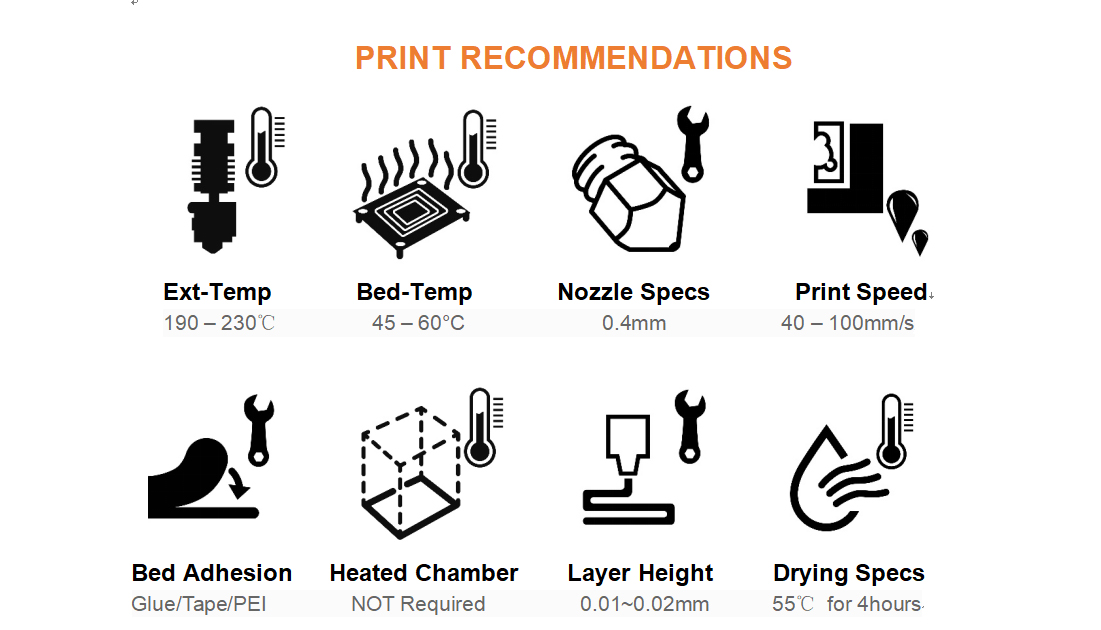

1. Kugira ngo ugere ku ngaruka nziza zo gucapa ukoresheje filament ya PLA y'ubudodo bw'amabara menshi, ni byiza gukoresha umurambararo w'umunwa wa mm 0.4 cyangwa muto. Umurambararo w'umunwa muto ushobora kugera ku buryo burambuye no ku bwiza bw'ubuso. Ubushyuhe bw'icapiro busabwa ni hagati ya 200-220°C, ubushyuhe bw'uburiri buri hagati ya 45-65°C. Umuvuduko mwiza wo gucapa ni hafi 50-60 mm/s, kandi uburebure bw'urwego bugomba kuba hagati ya mm 0.1-0.2.

2. Menya neza ko ushyira impera y'umugozi nyuma yo kuwukoresha igihe cyose, nko gushyira impera y'umugozi mu mwobo kugira ngo wirinde ko umugozi ugongana kugira ngo uzakoreshwe ubutaha.

3. Kugira ngo wongere igihe cy'uburemere bw'umugozi wawe, nyamuneka ubibike mu gikapu cyumye, gifunze cyangwa mu gasanduku.

| Ubushyuhe bwo gusohora (extruder)℃) | 190 – 230℃Byasabwe 215℃ |

| Ubushyuhe bwo ku buriri (℃) | Ubushyuhe bwa 45 – 65°C |

| NoIngano ya zzle | 0.4mm |

| Umuvuduko w'umufana | Ku 100% |

| Umuvuduko wo gucapa | 40 – 100mm/s |

| Igitanda gishyushye | Ubusa |

| Ahantu hasabwa kubaka | Ikirahure kirimo kole, impapuro zo gupfuka, kaseti y'ubururu, BuilTak, PEI |

Inama zo gucapa:

1) Kugira ngo ugere ku ngaruka nziza zo gucapa ukoresheje filament ya PLA y'ubudodo bw'amabara menshi, ni byiza gukoresha umurambararo w'umunwa wa mm 0.4 cyangwa muto. Umurambararo w'umunwa muto ushobora kugera ku buryo burambuye no ku bwiza bw'ubuso. Ubushyuhe bw'icapiro busabwa ni hagati ya 200-220°C, ubushyuhe bw'uburiri buri hagati ya 45-65°C. Umuvuduko mwiza wo gucapa ni hafi 50-60 mm/s, kandi uburebure bw'urwego bugomba kuba hagati ya mm 0.1-0.2.

2) Menya neza ko ushyira impera y'umugozi nyuma yo kuwukoresha igihe cyose, nko gushyira impera y'umugozi mu mwobo kugira ngo wirinde ko umugozi ugongana kugira ngo uzakoreshwe ubutaha.

3) Kugira ngo wongere igihe cy'uburemere bw'umugozi wawe, nyamuneka ubibike mu gikapu cyumye, gifunze cyangwa mu gasanduku.